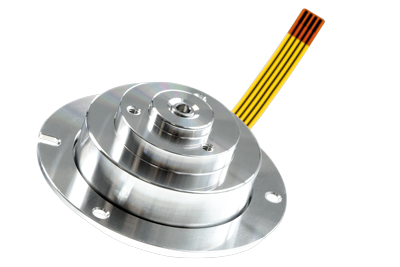

Fluid Dynamic Bearing (FDB)

Brushless DC Motor

BLDC motor with fluid dynamic bearing system

for high-precision applications

MinebeaMitsumi FDB Technology

The BLDC FDB SP2B motor combines experience and know-how with maximum precision. It connects the advantages of a brushless DC motor with the advanced technology of a fluid dynamic motor. FDB stands for Fluid Dynamic Bearing. In addition to the high speeds, low vibration and long life expectancy, the FDB motor impresses with numerous other advantages. Especially in the areas of "3D Laser Scanning", "LiDAR" and "Virtual Reality - Laser Tracking Scanner", the motor with its fluiddynamic bearing system is the right choice for high-precision applications.

BLDC with FDB-Technology

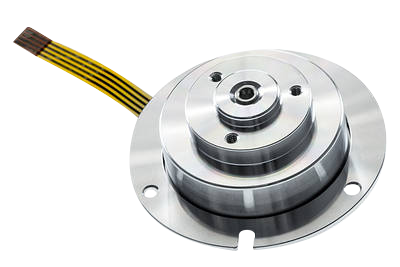

BLDC motor is commutated brushless and therefore electronically. There is no need for brushes as the torque is a function of the electronic action of the brushless motor on the commutator.

This means that a brushless motor has fewer components that can wear out, which makes it more durable and reliable.

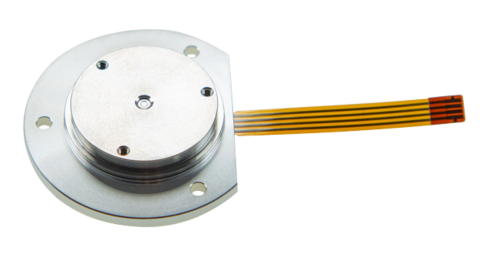

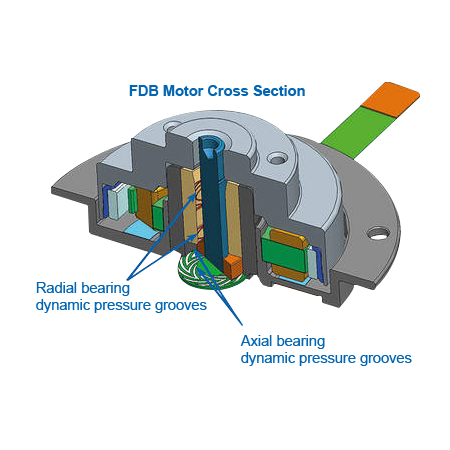

What is hidden behind the FDB motor?

The FDB motor was originally designed to meet the high-precision mechanical requirements and long life required by the hard disk market. The fluid dynamic bearing eliminates the limited precision of the ball bearings, minimizes the non-repeatable impact and reduces the acoustic noise level.

The FDB motor offers superior performance in terms of:

- extremely quiet and accurate running

- low vibration and low run out (NRRO below 40 nm)

- low acoustic noise level

- extremely long-lasting, since there are no wear parts

- high speeds up to 15,000 rpm

- Wobble error < 3" low

- low energy consumption

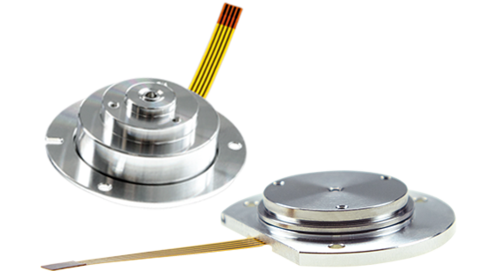

Our FDB motor provides higher precision and accuracy for you. Discover the combination of BLDC and FDB and discuss your unique application requirements with us.

Application areas

Safety Technology

High accuracy, low vibration, a wide field of vision as well as high axial and radial stiffness are only a few of the numerous virtues of our FDB motor in the area of safety technology. The motor allows high density and a wide viewing angle. Thanks to the compact design also smaller constructions in this application area are possible. The fluid dynamic bearing comes without the limited precision of ball bearings and minimizes the non-repeatable run out to optimize the steadiness.

Measurement Technology

With its wide temperature range, the BLDC FDB SP2B motor is ideally suited for indoor and outdoor applications. The FDB technology provides high density and accuracy. The small size and the high stiffness both fit perfectly when it comes to mobile application usage. Thanks to the combination of a brushless DC motor with the cutting-edge technology of fluid dynamic bearing, high running and scanning precision are guaranteed.

Consumer Electronics

The BLDC FDB SP2B motor provides the link to the real world. Due to its extremely quiet running and its accuracy, the level of noise is minimized. Furthermore the FDB motor allows a high density and turns virtual content into reality. The fluid dynamic bearing fulfils the high precision standards in consumer electronics. Since there are no wear parts, a long service life is guaranteed.

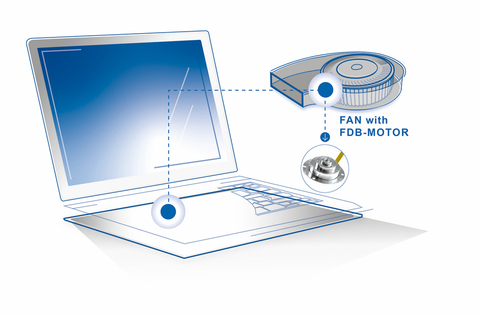

Fan with FDB Motor Technology

Now users of laptops and PCs can enjoy the silence of their devices. A barely perceptible whisper of the air flow, which is caused by the fan wheel, is the only noise noticeable. It is thanks to the stiffness of the motor that there is not even any vibration.

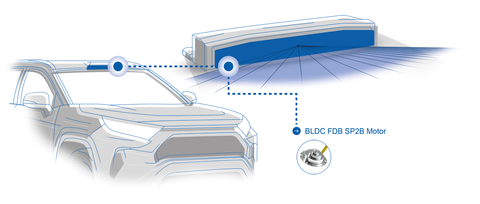

LIDAR systems

LIDAR stands for Light Detection and Ranging and is one of the most important technologies in the development of autonomous driving cars. With the help of the reflection of light waves, obstacles and their distances to the vehicle can be detected with a sensor. In the field of LIDAR, the BLDC FDB SP2B motor with extremely quiet running and very high accuracy is used based on these benefits. The advantages of the FDB motor in this area include its small size and long service life.